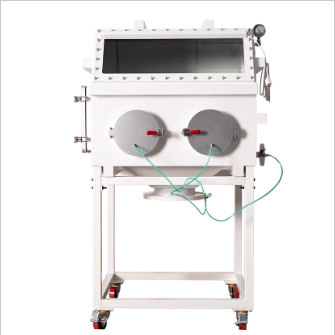

Βασικές Αρχές Λειτουργίας του Θαλάμου Χειρόνακτων

Ηρμητική Σφράγιση και Απομόνωση Ατμόσφαιρας

Η ηρμητική σφράγιση αποτελεί βασικό στοιχείο της κεφαλάκι με γάντια λειτουργίας του θαλάμου χειρόνακτων, καθώς εμποδίζει τη μόλυνση και διασφαλίζει ένα ελεγχόμενο περιβάλλον. Δημιουργώντας ένα αεροστεγές σφράγισμα, οι θάλαμοι χειρόνακτων απομονώνουν την εσωτερική τους ατμόσφαιρα από εξωτερικές επιρροές. Αυτό είναι κρίσιμο σε πεδία όπως τα φαρμακευτικά και η βιοτεχνολογία, όπου η διατήρηση της ασηψίας είναι ουσιώδης. Οι τεχνολογίες που χρησιμοποιούνται για αποτελεσματική σφράγιση περιλαμβάνουν ελαστικά παρεμβύσματα και προηγμένες μεθόδους σφράγισης. Αυτά τα υλικά παρέχουν ανθεκτικότητα και ευελιξία, διασφαλίζοντας ότι οι θάλαμοι χειρόνακτων παραμένουν αεροστεγείς ακόμη και υπό συχνή χρήση. Μελέτες δείχνουν ότι τα περιβάλλοντα που χρησιμοποιούν ηρμητική σφράγιση αντιμετωπίζουν σημαντικά χαμηλότερους ρυθμούς μόλυνσης σε σύγκριση με μη ηρμητικά συστήματα, επισημαίνοντας την αποτελεσματικότητά τους στη διατήρηση ενός καθαρού χώρου εργασίας.

Συστήματα Εκπλύσεως Αδρανούς Αερίου

Τα συστήματα εκκένωσης με αδρανή αέρια σε θαλάμους χειρισμού διαδραματίζουν καθοριστικό ρόλο στη δημιουργία περιβάλλοντος ελεύθερου οξυγόνου, το οποίο είναι απαραίτητο για το χειρισμό υλικών ευαίσθητων στον αέρα. Αδρανή αέρια όπως το άζωτο και το αργό χρησιμοποιούνται για να αντικαταστήσουν το ατμοσφαιρικό οξυγόνο, αποτρέποντας έτσι την οξείδωση και την υποβάθμιση ευαίσθητων δειγμάτων. Οι λειτουργικές φάσεις της εκκένωσης περιλαμβάνουν αρχική πλύση με αέριο για την αφαίρεση του ατμοσφαιρικού αέρα, ακολουθούμενη από συνεχή ροή για τη διατήρηση χαμηλών επιπέδων οξυγόνου. Μελέτες και βιομηχανικά πρότυπα επισημαίνουν την αναγκαιότητα τέτοιων συστημάτων σε εφαρμογές όπως η παραγωγή ημιαγωγών και η επιστήμη των υλικών, όπου ακόμη και ίχνη οξυγόνου μπορούν να θέσουν σε κίνδυνο την ακεραιότητα της διεργασίας.

Μηχανισμοί Ακριβούς Ελέγχου Περιβάλλοντος

Οι μηχανισμοί ακριβούς ελέγχου του περιβάλλοντος στα γάντια είναι κρίσιμοι για τη διατήρηση της ακεραιότητας και της συνέπειας των δειγμάτων στα πειράματα. Αυτά τα συστήματα ρυθμίζουν τη θερμοκρασία και την υγρασία, εξασφαλίζοντας ιδανικές συνθήκες για ευαίσθητες διεργασίες. Τα προηγμένα γάντια είναι εξοπλισμένα με αισθητήρες και συστήματα παρακολούθησης που παρέχουν πληροφορίες σε πραγματικό χρόνο, επιτρέποντας ακριβείς ρυθμίσεις και διατηρώντας σταθερές συνθήκες. Μελέτες περιπτώσεων από τη βιομηχανία έχουν δείξει ότι ο ακριβής έλεγχος του περιβάλλοντος μπορεί σημαντικά να επηρεάσει τα αποτελέσματα της έρευνας, βελτιώνοντας τόσο την αναπαραγωγιμότητα όσο και την αξιοπιστία των αποτελεσμάτων. Αυτή η ακρίβεια είναι ιδιαίτερα πολύτιμη σε τομείς υψηλού κινδύνου, όπως η φαρμακευτική και η σύνθεση προηγμένων υλικών.

Προηγμένες Τεχνολογίες Φιλτραρίσματος σε Γάντια

Φίλτρα HEPA/ULPA για Απομάκρυνση Σωματιδίων

Η διάκριση μεταξύ φίλτρων HEPA και ULPA είναι κρίσιμης σημασίας στο πλαίσιο των θαλάμων αδρανούς ατμόσφαιρας. Ενώ τα φίλτρα HEPA μπορούν να αποτρέψουν σωματίδια μέχρι 0,3 μικρά με απόδοση 99,97%, τα φίλτρα ULPA προχωρούν περισσότερο, φιλτράροντας σωματίδια μέχρι 0,12 μικρά με απόδοση 99,999%. Αυτά τα μεγέθη είναι σημαντικά για την τήρηση αυστηρών εργαστηριακών προτύπων, όπου η διατήρηση καθαρών ατμοσφαιρών είναι απαραίτητη. Τα εργαστήρια που χειρίζονται ηλεκτρονικά εξαρτήματα ή εργάζονται με ευαίσθητα βιολογικά δείγματα συχνά βασίζονται στα φίλτρα HEPA και ULPA λόγω της ικανότητάς τους να ελέγχουν υπερλεπτά σωματίδια.

Συστήματα Χημικής Φιλτραρίσματος

Τα συστήματα χημικής φιλτραρίσματος στα γάντζια λειτουργούν αφαιρώντας επιβλαβείς αέριους και ατμούς για να εξασφαλίσουν ένα ασφαλές περιβάλλον εργασίας. Αυτά τα φίλτρα χρησιμοποιούν συνήθως ενεργοποιημένο άνθρακα και άλλα υλικά που προσροφούν, τα οποία εξουδετερώνουν αποτελεσματικά συγκεκριμένα επικίνδυνα χημικά. Για παράδειγμα, οι βιομηχανίες που χειρίζονται πτητικές οργανικές ενώσεις ή αντιδραστήρια αέρια πρέπει να συμμορφώνονται με περιβαλλοντικούς κανονισμούς, όπως αυτοί που έχει θεσπίσει ο Οργανισμός Προστασίας του Περιβάλλοντος (EPA), οι οποίοι επιβάλλουν τη χρήση τέτοιων προηγμένων συστημάτων φιλτραρίσματος. Αυτή η ανάγκη τονίζεται ιδιαίτερα σε τομείς όπως η φαρμακευτική και η χημική παραγωγή, όπου η έκθεση σε τοξικές αναθυμιάσεις πρέπει να ελαχιστοποιείται.

Διατήρηση Στερείλων Συνθηκών

Η διατήρηση στείρων συνθηκών μέσα σε θάλαμο γαντιών περιλαμβάνει την ενσωμάτωση μεθόδων όπως η υπεριώδης ακτινοβολία και η φιλτραρισμός HEPA. Η υπεριώδης ακτινοβολία απολυμαίνει τις επιφάνειες, εξαλείφοντας μικροοργανισμούς που οι φίλτρα HEPA ίσως δεν μπορούν να απομονώσουν πλήρως. Αυτή η διπλή προσέγγιση είναι ζωτικής σημασίας σε φαρμακευτικά και ερευνητικά περιβάλλοντα, όπου η μόλυνση μπορεί να απειλήσει την ακεραιότητα των δειγμάτων ή τα αποτελέσματα των πειραμάτων. Για παράδειγμα, οι κατευθυντήριες γραμμές της βιομηχανίας τονίζουν τις απαιτήσεις στείρας τεχνικής για τη διασφάλιση αυστηρού ελέγχου μόλυνσης, όπως αναφέρεται σε δημοσιεύσεις οργανισμών όπως ο Παγκόσμιος Οργανισμός Υγείας (WHO). Αυτές οι τεχνικές είναι κρίσιμες για εφαρμογές στις επιστήμες της ζωής και τη βιοτεχνολογία, όπου η διατήρηση της στειρότητας είναι απαραίτητη.

Ειδικές Διαμορφώσεις και Εφαρμογές ανά Κλάδο

Φαρμακευτικές και Βιοτεχνολογικές Εφαρμογές

Τα κιτρώνια είναι απαραίτητα στις φαρμακευτικές και βιοτεχνολογικές βιομηχανίες λόγω των αυστηρών απαιτήσεων για ασηψία και έλεγχο μόλυνσης. Σε αυτές τις βιομηχανίες, τα κιτρώνια είναι απαραίτητα για τη διαμόρφωση φαρμάκων, την παραγωγή εμβολίων και το χειρισμό ευαίσθητων βιολογικών υλικών, διασφαλίζοντας ότι τα προϊόντα παραμένουν ελεύθερα από μόλυνση. Για παράδειγμα, κατά τη διάρκεια της πανδημίας του COVID-19, τα κιτρώνια διαδραμάτισαν κρίσιμο ρόλο στην ανάπτυξη και δοκιμή εμβολίων διατηρώντας ασηπείς συνθήκες. Οι κανονιστικές προδιαγραφές, όπως αυτές της FDA και της ΕΕ, επιβάλλουν τη χρήση κιτρωνιών για να διασφαλιστούν τα υψηλότερα επίπεδα ασφάλειας και αποτελεσματικότητας των προϊόντων.

Παραγωγή ημιαγωγών και ηλεκτρονικών

Στους τομείς των ημιαγωγών και της ηλεκτρονικής, τα γάντια κουτιά είναι κρίσιμα για την πρόληψη μόλυνσης κατά τις διαδικασίες παραγωγής. Οι σωματίδιες και οι ακαθαρσίες στον αέρα μπορούν να επηρεάσουν αρνητικά την ποιότητα των πλακών ημιαγωγών, επηρεάζοντας τα ποσοστά παραγωγής και μειώνοντας τη διάρκεια ζωής του εξοπλισμού. Ως εκ τούτου, τα γάντια κουτιά σχεδιάζονται για να πληρούν συγκεκριμένα πρότυπα του κλάδου και απαιτήσεις των OEM, παρέχοντας ένα ελεγχόμενο περιβάλλον που ελαχιστοποιεί τους κινδύνους μόλυνσης. Η σχεδίαση του γάντιου κουτιού, το οποίο συχνά ενσωματώνει προηγμένα συστήματα φιλτραρίσματος και παρακολούθησης, είναι απαραίτητη για τη διατήρηση των προτύπων καθαρών δωματίων και τη βελτίωση της ποιότητας των προϊόντων.

Πυρηνική Έρευνα και Χειρισμός Επικίνδυνων Υλών

Για την πυρηνική έρευνα και τη χειριστική επικίνδυνων υλικών, τα γάντια κουτιά είναι απαραίτητα για τη διασφάλιση ασφαλών και ελεγχόμενων περιβαλλόντων. Αυτά τα κουτιά επιτρέπουν στους ερευνητές να χειρίζονται ραδιενεργά ουσίες με ασφάλεια, ελαχιστοποιώντας τους κινδύνους έκθεσης και μόλυνσης. Η τήρηση των διεθνών προτύπων ασφαλείας, όπως αυτά που καθορίζονται από το Διεθνές Πρακάστρο Ατομικής Ενέργειας (IAEA), είναι κρίσιμη σε αυτά τα περιβάλλοντα. Έχουν υπάρξει περιπτώσεις όπου η σωστή χρήση γάντιων κουτιών απέτρεψε πιθανά ατυχήματα, επισημαίνοντας τη σημασία τους. Για παράδειγμα, κατά τη διάρκεια πειραμάτων με ραδιενεργούς ισοτόπους, τα γάντια κουτιά έχουν επιτύχει τον περιορισμό της μόλυνσης και την προστασία του προσωπικού.

Ενεργειακή Απόδοση και Βιώσιμος Σχεδιασμός Γάντιων Κουτιών

Μειωμένη Κατανάλωση Αερίου μέσω Ανακυκλοφορίας

Η βελτίωση της ενεργειακής απόδοσης των κιβωτίων γάντιων μέσω προηγμένων μεθόδων ανακύκλωσης μειώνει σημαντικά την κατανάλωση αερίου, με αποτέλεσμα να μειώνονται τα λειτουργικά έξοδα. Με την ενσωμάτωση συστημάτων ανακύκλωσης, τα κιβώτια γάντι μπορούν να ελαχιστοποιήσουν την απώλεια ακριβά αέρια όπως το άζωτο ή το αργόνο, τα οποία είναι απαραίτητα για τη διατήρηση αδρανών περιβάλλοντων. Για παράδειγμα, τα σχέδια κλειστού κύκλου ανακύκλωσης ανακυκλώνουν και καθαρίζουν αποτελεσματικά τα αέρια μέσα στο κιβώτιο γάντι, εξασφαλίζοντας ελάχιστες απορρίψεις. Μελέτες έχουν δείξει ότι τα συστήματα αυτά ενισχύουν τη βιωσιμότητα με τη βελτιστοποίηση της χρήσης αερίου και τη μείωση των εκπομπών. Η εφαρμογή αυτών των τεχνολογιών όχι μόνο εξοικονομεί έξοδα αλλά προάγει επίσης τη διατήρηση του περιβάλλοντος μειώνοντας το συνολικό ενεργειακό αποτύπωμα των εργαστηριακών εργασιών.

Συστήματα έξυπνης παρακολούθησης για τη βελτιστοποίηση των πόρων

Η ενσωμάτωση των έξυπνων συστημάτων παρακολούθησης που υποστηρίζονται από το IoT σε κιβώτια γάντι διευκολύνει την βελτιστοποίηση των πόρων και ενισχύει την επιχειρησιακή αποτελεσματικότητα. Τα έξυπνα συστήματα αυτά παρακολουθούν σε πραγματικό χρόνο μετρήσεις απόδοσης όπως επίπεδα αερίων, θερμοκρασία και υγρασία, επιτρέποντας ακριβείς ρυθμίσεις που μειώνουν την περιττή κατανάλωση. Για παράδειγμα, οι αισθητήρες στα κιβώτια των γάντι μπορούν να ειδοποιήσουν τους χρήστες όταν μια παράμετρος αποκλίνει από το βέλτιστο εύρος της, αποτρέποντας έτσι την σπατάλη πόρων. Στην πράξη, οι εγκαταστάσεις που χρησιμοποιούν αυτά τα συστήματα έχουν αναφέρει αισθητές μειώσεις στην αξιοποίηση των πόρων, καθώς η συνεχής παρακολούθηση των δεδομένων διευκολύνει την τεκμηριωμένη λήψη αποφάσεων. Μια μελέτη περιπτώσεων σε φαρμακευτικό περιβάλλον αποκάλυψε ότι τα έξυπνα συστήματα μείωσαν τη χρήση αερίου έως και κατά 20%, αποδεικνύοντας σημαντικές βελτιώσεις στη βιωσιμότητα και την λειτουργική απόδοση.

Συγκριτική εξοικονόμηση ενέργειας έναντι παραδοσιακών μεθόδων

Κατά τη σύγκριση των σύγχρονων θηκών γαντιών με παραδοσιακές εργαστηριακές διαμορφώσεις, είναι προφανής η εξοικονόμηση ενέργειας που επιτυγχάνεται με τα σύγχρονα σχέδια. Οι παραδοσιακές μέθοδοι περιορισμού, όπως οι απορροφητήρες καπνού, απαιτούν συνεχή ροή αέρα και σημαντική κατανάλωση ενέργειας, κάτι που δεν ισχύει για τις σφραγισμένες θήκες γαντιών. Τα σύγχρονα σχέδια διατηρούν αποτελεσματικά ελεγχόμενες ατμόσφαιρες χωρίς συνεχή ανταλλαγή αέρα, μειώνοντας ριζικά τις ανάγκες σε ενέργεια. Στατιστικά στοιχεία από μελέτες ενεργειακής απόδοσης δείχνουν ότι η χρήση θηκών γαντιών μπορεί να μειώσει την κατανάλωση ενέργειας κατά περίπου 30% σε σύγκριση με τις παραδοσιακές μεθόδους. Αυτή η εξοικονόμηση δείχνει τη δυνατότητα των θηκών γαντιών να συμβάλλουν σε πιο βιώσιμα εργαστηριακά περιβάλλοντα, διατηρώντας ταυτόχρονα υψηλά πρότυπα ασφάλειας και ακρίβειας στις επιστημονικές λειτουργίες.

Τεχνολογικές Καινοτομίες σε Σύγχρονες Θήκες Γαντιών

Ενσωμάτωση IoT και Αυτοματοποίησης

Η ενσωμάτωση της τεχνολογίας IoT έχει βελτιώσει σημαντικά τη λειτουργικότητα των σύγχρονων θηκών γάντιων, παρέχοντας αδιάκοπη συνδεσιμότητα και απόκτηση δεδομένων σε πραγματικό χρόνο. Αυτή η συνδεσιμότητα επιτρέπει βελτιωμένο έλεγχο διεργασιών μέσω αυτοματοποίησης, μειώνοντας τα ανθρώπινα λάθη και αυξάνοντας την αποδοτικότητα. Για παράδειγμα, τα συστήματα ενισχυμένα με IoT μπορούν να παρακολουθούν διάφορες παραμέτρους, όπως την υγρασία και τη θερμοκρασία, και να τις ρυθμίζουν αυτόματα για να διατηρούν ιδανικές συνθήκες. Ένα παράδειγμα αυτής της τεχνολογίας σε λειτουργία φαίνεται σε διάφορες φαρμακευτικές εταιρείες που χρησιμοποιούν συστήματα IoT στις θήκες γάντιων για να διασφαλίζουν την ακεραιότητα ευαίσθητων περιβαλλόντων έρευνας. Η ενσωμάτωση αυτή προσφέρει σημαντικές βελτιώσεις στη λειτουργία, σύμφωνα με την αυξανόμενη ζήτηση της βιομηχανίας για ακρίβεια και αξιοπιστία.

Έλεγχος Διεργασιών με Τεχνητή Νοημοσύνη

Οι τεχνολογίες τεχνητής νοημοσύνης μεταμορφώνουν τον τρόπο διαχείρισης των θαλάμων χειρισμού αέρα προβλέποντας και βελτιστοποιώντας τις περιβαλλοντικές συνθήκες. Τα συστήματα με βάση την τεχνητή νοημοσύνη διευκολύνουν τον προηγμένο έλεγχο του περιβάλλοντος των θαλάμων χειρισμού αέρα, επιτρέποντας την προληπτική συντήρηση και τη βελτιστοποίηση διεργασιών. Για παράδειγμα, ορισμένα εργαστήρια χρησιμοποιούν τεχνητή νοημοσύνη για τον αυτόματο έλεγχο των επιπέδων αερίων και την ανακύκλωση αδρανών αερίων, βελτιώνοντας τη βιωσιμότητα και τη λειτουργική απόδοση. Η έρευνα σε ελεγχόμενα περιβάλλοντα επισημαίνει τη δυνατότητα της τεχνητής νοημοσύνης να μειώσει σημαντικά την κατανάλωση ενέργειας και τα λειτουργικά κόστη, καθιστώντας την έναν βασικό παράγοντα στην εξέλιξη των εργαστηριακών τεχνολογιών. Αξιοποιώντας την τεχνητή νοημοσύνη, τα εργαστήρια μπορούν να βελτιστοποιήσουν τις διεργασίες, εξασφαλίζοντας καλύτερη ασφάλεια, ακρίβεια και παραγωγικότητα.

Μοντουλωτές και Κλιμακώσιμες Σχεδιαστικές Λύσεις Συστημάτων

Η τάση προς μονταρισμένα και κλιμακώσιμα σχέδια γάντιων κουτιών αποκτά ένταση σε περιβάλλοντα έρευνας και παραγωγής λόγω της προσαρμοστικότητας και της κλιμάκωσης. Αυτά τα σχέδια επιτρέπουν στους οργανισμούς να προσαρμόζουν τα συστήματά τους σε συγκεκριμένες ανάγκες και να επεκτείνουν τη χωρητικότητα όπως απαιτείται, χωρίς να αλλάξουν τις υπάρχουσες διαμορφώσεις. Η κλιμάκωση των κουτιών γαντιών είναι ιδιαίτερα πλεονεκτική σε περιβάλλοντα έρευνας όπου οι διαφοροποιημένες λειτουργικές απαιτήσεις είναι συνηθισμένες. Μαρτυρίες χρηστών επισημαίνουν την αποτελεσματικότητα των μονταρισμένων σχεδίων στην παροχή οικονομικά αποδοτικών και ευέλικτων λύσεων που υποστηρίζουν τόσο τις τρέχουσες όσο και τις μελλοντικές λειτουργικές απαιτήσεις.

Για περισσότερες πληροφορίες σχετικά με την ενσωμάτωση IoT και AI σε κουτιά γαντιών, μπορείτε να επισκεφτείτε την Terra Universal, Inc, η οποία προσφέρει εκτεταμένες γνώσεις σχετικά με τις σύγχρονες τεχνολογίες κουτιών γαντιών.

Τμήμα Γενικών Ερωτήσεων

Ποιος είναι ο σκοπός της αεροστεγούς σφράγισης στα κουτιά γαντιών; Η αεροστεγής σφράγιση στα γάντια είναι ζωτικής σημασίας για την πρόληψη μόλυνσης και τη διασφάλιση ενός ελεγχόμενου περιβάλλοντος, απομονώνοντας την εσωτερική ατμόσφαιρα από εξωτερικές επιρροές.

Γιατί είναι σημαντικά τα συστήματα αδρανούς αερίου στα γάντια; Τα συστήματα αδρανούς αερίου δημιουργούν περιβάλλον χωρίς οξυγόνο, το οποίο είναι απαραίτητο για την ασφαλή χειριστική υλικών ευαίσθητων στον αέρα, αντικαθιστώντας το ατμοσφαιρικό οξυγόνο.

Πώς τα σύγχρονα γάντια εξοικονομούν ενέργεια σε σύγκριση με τις παραδοσιακές εργαστηριακές διαμορφώσεις; Τα σύγχρονα γάντια διατηρούν ελεγχόμενα περιβάλλοντα χωρίς συνεχή ανταλλαγή αέρα, μειώνοντας την κατανάλωση ενέργειας έως και 30% σε σύγκριση με τις παραδοσιακές μεθόδους.

Ποιές τεχνολογικές βελτιώσεις έχουν ενσωματωθεί στα γάντια; Τα προηγμένα γάντια περιλαμβάνουν συστήματα ενισχυμένα με IoT για παρακολούθηση σε πραγματικό χρόνο και έλεγχο διαδικασιών με χρήση τεχνητής νοημοσύνης, βελτιστοποιώντας τις περιβαλλοντικές συνθήκες και αυξάνοντας την αποδοτικότητα.