Pharmaceutical and Biotechnology Industries

Sterile Drug Formulation and Compounding

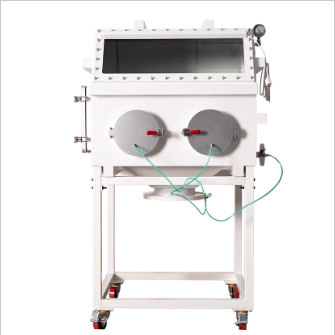

Glove boxes play an essential role in maintaining sterility during critical drug formulation processes. These enclosed environments ensure that pharmaceutical Products are compounded in sterile conditions, minimizing contamination and preserving drug integrity. There are different types of sterile environments utilized, such as Class II and Class III glove boxes, each offering varying levels of contamination control and protection. In non-controlled environments, contamination levels can be significantly higher, with a study showing average contamination rates reaching 25% as opposed to less than 5% in controlled glove box settings. The use of glove boxes in sterile drug formulation not only aids in producing high-quality products but also helps in adhering to stringent industry regulations, safeguarding public health.

Handling Cytotoxic Agents in Cancer Research

The use of glove boxes in cancer research for handling cytotoxic agents is paramount, ensuring both researcher safety and drug efficacy. These protective environments enforce strict safety protocols, such as double-gloving and physical barriers, to prevent exposure to hazardous materials. Regulatory entities like OSHA mandate specific guidelines for handling cytotoxic drugs, emphasizing the importance of personal protective equipment (PPE) and controlled environments. Experts in the field highlight that proper handling procedures within glove boxes enhance researcher safety and uphold the integrity of the drugs being studied. This secure method allows researchers to focus on innovative cancer treatments without compromising their safety or the efficacy of experimental drugs.

Controlled Environments for Vaccine Development

Glove boxes are vital in creating controlled environments for the formulation and testing of vaccines. These specialized spaces ensure that all vaccine components remain uncontaminated, which is crucial in achieving effective immunizations. Recent studies have shown that vaccine development in controlled environments like glove boxes results in higher success rates due to reduced contamination risk. Ensuring the purity and sterility of vaccine formulations is critical, as contamination can greatly affect potency and safety. With glove boxes facilitating safe handling and production conditions, the pharmaceutical industry can efficiently produce vaccines that are reliable and essential for global health initiatives.

Semiconductor and Electronics Manufacturing

Wafer Processing in Cleanroom Environments

Glove boxes are indispensable in wafer processing to ensure the effective elimination of contaminants during manufacturing. In cleanroom environments, even the smallest particulate can lead to significant failure rates in semiconductor products, reducing yield and affecting overall production quality. Research shows that contamination in uncontrolled environments contributes to a higher failure rate in semiconductor products, emphasizing the need for stringent control measures. Glove boxes provide manufacturers with a controlled atmosphere that shields wafers from external variables, enabling precise processes essential for high-quality semiconductor production. This necessity underscores why industries commonly use glove boxes for safety and precision in cleanroom settings.

OLED Production Under Inert Gas Conditions

Maintaining inert gas conditions is crucial for OLED material production, and glove boxes perfectly facilitate these environments. The sensitive nature of OLED components necessitates protection from air and moisture, which can degrade materials. Statistics indicate a notable improvement in product yield when glove boxes are utilized, as these boxes ensure consistent inert gas environments. The integration of glove boxes in manufacturing processes has also sparked technological innovations that have enhanced electronics production. Moreover, glove boxes have played a pivotal role in advancing manufacturing techniques, making them vital for industries striving for precision and quality.

Precision Assembly of Microelectronic Components

The precision assembly of microelectronic components demands an environment free of contaminants and equipped to uphold industry standards for quality assurance. Glove boxes fulfill these requirements, offering manufacturers the cleanliness and control needed to meet rigorous assembly standards. Standards such as those set by ISO demonstrate the necessity for precision in processes involving microelectronic components. Experts in the electronics field continually emphasize the growing need for advanced glove boxes as technology advances in manufacturing. This demand reflects the industries' reliance on glove boxes to ensure that precision and cleanliness are maintained at every step in the assembly process.

Medical and Healthcare Applications

Surgical instrument sterilization protocols

The role of glove boxes in the sterilization of surgical instruments is crucial for ensuring patient safety. They provide an isolated and controlled environment that prevents contamination during the sterilization process, offering a significant impact on infection control rates. For instance, hospitals observing strict sterilization protocols report significantly lower infection rates, attributing this success to the use of glove boxes. These boxes comply with stringent health regulations, facilitating the necessary conditions for sterilizing medical instruments effectively [Summit, 2025 Safety Digital Summit].

Isolation of sensitive biomedical samples

Glove boxes are essential for isolating and protecting sensitive biomedical samples from contamination during research. By maintaining a sterile environment, glove boxes help preserve the viability of biological samples, which is critical for accurate research outcomes. Studies have demonstrated that using glove boxes for sample isolation significantly enhances the integrity and durability of specimens, leading to more reliable research results. Best practices for sample isolation include regular calibration and maintenance of glove box conditions to ensure that they continually meet the desired standards.

Radioactive pharmaceutical preparation

In the preparation of radioactive pharmaceuticals, glove boxes provide indispensable safety measures, shielding medical personnel from radiation exposure while handling dangerous materials. Regulatory guidelines necessitate using controlled environments, such as glove boxes, to ensure both the safety of professionals and the integrity of pharmaceutical products. These boxes enable hospitals and labs to comply with safety standards while enhancing operational efficacy, showcasing their vital role in mitigating risks associated with preparing radiopharmaceuticals.

Chemical Research and Advanced Materials

Nanomaterial Synthesis Under Controlled Atmospheres

Glove boxes play a pivotal role in the synthesis of nanomaterials by providing a controlled environment that prevents contamination. These enclosed spaces are essential for maintaining an inert atmosphere, ensuring that reactive materials do not interact with oxygen or moisture. Recent studies have shown that nanomaterials synthesized in glove boxes exhibit higher quality and more predictable properties compared to those produced without these controlled conditions. The precise atmospheric control offered by glove boxes significantly influences the structural, optical, and electronic properties of nanomaterials, highlighting their importance in high-precision applications in industries like electronics and pharmaceuticals.

Pyrophoric Substance Handling in Catalysis Studies

Handling pyrophoric substances in catalysis studies involves critical safety measures, with glove boxes being central to ensuring safety and efficacy. Pyrophoric substances can spontaneously ignite upon exposure to air, posing significant risks in laboratory settings. Statistics reveal that many laboratory incidents stem from improper handling of such materials; hence, glove boxes, which provide an oxygen-free environment, are vital in minimizing these risks. Advances in laboratory safety standards, influenced by glove box technology, have successfully reduced incidents, ensuring safer research processes and fostering confidence among researchers when working with hazardous materials.

Air-Sensitive Battery Component Development

In the development of air-sensitive battery components, such as lithium batteries, glove boxes are indispensable. They prevent exposure of reactive elements to the atmosphere, crucial for maintaining the integrity and performance of these materials. Industry statistics underscore the reliability of batteries developed in such controlled environments, with fewer defects and improved longevity. Innovations in battery technology, often arising from advanced glove box systems, have led to significant improvements in energy storage solutions, aligning with the growing demand for efficient and durable power sources in sectors ranging from consumer electronics to electric vehicles.

Environmental Science and Energy Innovation

Analysis of Atmospheric Contaminants

The use of glove boxes is crucial in the analysis of atmospheric contaminants, ensuring that researchers can work in controlled environments free from unwanted external variables. By maintaining consistent atmospheric conditions, glove boxes prevent contamination during sample collection and analysis, which is essential for accurate data. Studies indicate that employing glove boxes in environmental research enhances the quality and reliability of collected data, making it easier to comply with environmental regulation standards. This accuracy is paramount, as errors in contaminant analysis can lead to non-compliance with regulatory bodies, potentially resulting in significant environmental harm and financial penalties.

Lithium-ion Battery Cell Assembly

Glove boxes are indispensable in the assembly of lithium-ion batteries because they prevent the exposure of sensitive components to moisture and oxygen, which could otherwise lead to battery degradation. Statistical data shows that the consistent use of glove boxes in battery assembly processes improves the overall quality and longevity of lithium-ion batteries, meeting industry standards. With ongoing advancements in battery technology, trend analyses reveal an increasing reliance on glove boxes to ensure high performance and safety, underscoring their importance in the evolving energy sector.

Hydrogen Fuel Research Containment

In the realm of hydrogen fuel research, glove boxes play a vital role in maintaining the safety of researchers and the integrity of experiments. The properties of hydrogen make it susceptible to combustion and leakage, necessitating a carefully controlled environment. Research evidence underscores that in the presence of glove boxes, researchers can study hydrogen fuel applications more safely and effectively. As the future pivots towards hydrogen as a sustainable energy source, glove boxes are expected to continue facilitating innovation, supporting ongoing advances in this field while ensuring researcher safety.

FAQ

What are glove boxes used for in pharmaceutical industries?

Glove boxes in pharmaceutical industries are used to maintain sterility during drug formulation and compounding processes, ensuring minimal contamination and compliance with industry regulations.

How do glove boxes ensure safety in cancer research?

Glove boxes in cancer research provide a controlled environment to handle cytotoxic agents safely, protecting researchers from exposure while maintaining the integrity of the drugs being studied.

Why are glove boxes necessary for semiconductor manufacturing?

In semiconductor manufacturing, glove boxes help eliminate contaminants in cleanroom environments, which is critical to maintaining product quality and reducing failure rates.

How do glove boxes contribute to the development of vaccines?

Glove boxes create controlled environments that protect vaccine components from contamination, enhancing the purity and effectiveness of immunizations.

What role do glove boxes play in handling radioactive pharmaceuticals?

They ensure safety by providing a controlled environment during the preparation of radioactive pharmaceuticals, protecting medical personnel from radiation exposure.

Table of Contents

- Pharmaceutical and Biotechnology Industries

- Semiconductor and Electronics Manufacturing

- Medical and Healthcare Applications

- Chemical Research and Advanced Materials

- Environmental Science and Energy Innovation

-

FAQ

- What are glove boxes used for in pharmaceutical industries?

- How do glove boxes ensure safety in cancer research?

- Why are glove boxes necessary for semiconductor manufacturing?

- How do glove boxes contribute to the development of vaccines?

- What role do glove boxes play in handling radioactive pharmaceuticals?