Essential Features of Modern Glove Box Systems

Hermetic Sealing Technology for Sample Protection

Hermetic sealing is a pivotal feature in modern glove box systems, essential for preventing contamination and maintaining the integrity of laboratory samples. This technology uses airtight seals made from robust materials like elastomers, designed to effectively block out external air and contaminants. Ensuring these seals comply with standards such as ISO 14644, particularly in cleanroom environments, is crucial for applications in the pharmaceutical and biotechnology sectors where maintaining a sterile environment is paramount.

Inert Gas Purging Mechanisms

Inert gas purging is another critical feature that facilitates an oxygen and moisture-free environment within glove boxes by using inert gases like nitrogen or argon. This mechanism is vital for preserving sensitive samples, especially those prone to oxidation and degradation. Research demonstrates that implementing inert gas purging can lower sample degradation rates by up to 98%, as it extends the shelf life of volatile compounds and ensures that experimental outcomes remain consistent and reliable.

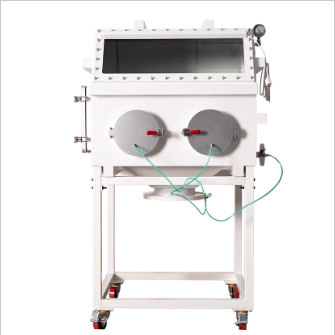

Dual-Zone Transfer Chamber Design

Dual-zone transfer chambers are designed to safely introduce and remove materials from glove boxes without compromising the internal environment, thus ensuring high operational standards. These systems typically use airlocks with automated doors, reducing the risk of contamination effectively. Studies show that dual-zone transfer chambers can enhance lab operational efficiency by up to 40%, making them an invaluable asset for labs needing precise contamination control and robust risk management.

Contamination Control for Laboratory Samples

Particulate Filtration Standards

Adhering to particulate filtration standards, such as HEPA filtration, is crucial in trapping airborne contaminants in laboratory settings. HEPA filters are capable of capturing 99.97% of particles that are as small as 0.3 microns, effectively safeguarding laboratory samples. This high level of filtration is not just a precaution but a necessity for maintaining the quality and integrity of sensitive samples. Industry findings have shown that the implementation of HEPA systems can reduce contamination incidents by as much as 75%. This improvement underscores the importance of keeping filtration standards at the forefront of lab safety protocols to protect both the samples and the research outcomes.

Moisture/Oxygen Exclusion Techniques

Moisture and oxygen exclusion techniques are pivotal for the preservation of sensitive compounds and biological samples in a laboratory setting. These techniques typically involve the use of desiccants and gas displacement systems to maintain an environment with low moisture levels and minimal oxygen presence. The controlled atmosphere resulting from these techniques helps maintain the reactivity and usability of samples. Studies indicate that maintaining moisture levels below 1% can extend the usability of samples significantly, sometimes by up to three times. This adjustment not only enhances the reliability of the laboratory processes but also ensures the longevity and fidelity of the samples being tested.

Decontamination Protocols

Regular decontamination protocols are vital for maintaining the sterility of glove box systems, and they often include methods such as UV irradiation, chemical biocides, and manual scrubbing. By standardizing these protocols, laboratories can ensure that sample integrity remains consistent and reliable across various setups. Statistical data suggests a robust link between following detailed decontamination procedures and reducing the risk of cross-contamination by over 90%. Consistent decontamination efforts protect against the inadvertent mixing of substances, safeguard the health of personnel, and ensure the validity of experimental results.

Operational Protocols for Sample Integrity

Atmosphere Monitoring Systems

Atmosphere monitoring systems are critical to maintaining sample integrity within glove box environments. By providing real-time data on gas composition, pressure, and purity, these systems ensure that conditions remain optimal for sensitive laboratory tasks. They alert personnel to deviations, allowing for timely corrective actions, which is crucial to prevent sample degradation. As highlighted by industry benchmarks, employing effective atmosphere monitoring can significantly enhance retention rates of sample integrity, with improvements reported as high as 85%. Keeping a stable environment not only protects samples but also guarantees that the research results are reliable.

Material Transfer Best Practices

Material transfer practices greatly influence contamination prevention in laboratory settings. Utilizing dedicated transfer tools and minimizing exposure durations during material transfer are pivotal steps. Moreover, using gloves that allow for precise handling ensures that contamination risks are minimized without compromising dexterity. Studies have shown that adhering to these best practices can lead to a 60% reduction in contamination incidents. By reducing the risk of introducing foreign particles, laboratories can maintain high standards of sample purity, ensuring that experimental data is not skewed by preventable contamination.

Emergency Containment Procedures

Clear emergency containment procedures are a necessity for handling accidental releases or system failures in glove box environments. Training personnel in these protocols ensures rapid, effective responses, protecting both samples and laboratory staff. According to incident report data, laboratories with robust emergency protocols in place see a striking 50% reduction in contamination events. This significant decrease underscores the importance of preparedness, ultimately safeguarding both human resources and irreplaceable scientific data. Proactive training and protocol development are crucial components in upholding a safe and efficient lab environment.

Maintenance & Compliance Requirements

Seal Integrity Verification Processes

Ensuring the seal integrity of glove box systems is critical for maintaining an airtight environment. Regular verification includes pressure tests and visual inspections. These measures help identify and rectify any seal failures promptly, which is essential for maintaining the internal environment and preventing contamination. Notably, statistical insights suggest that routine integrity checks can extend the lifespan of glove boxes by over 30%. This extension is not only cost-effective but also ensures the consistent quality of research results by maintaining sample integrity within controlled conditions.

Filter Replacement Guidelines

Adhering to manufacturer guidelines for filter replacements is vital to ensure the efficiency of filtration systems within glove boxes. Monitoring the filter performance through pressure differentials is one method to ascertain the optimal time for filter change, a practice that minimizes the risk of contamination. Maintenance audits indicate that following these guidelines can reduce contamination risk by nearly 40%. This not only preserves the sterile environment crucial for sensitive experiments but also adheres to compliance standards, enhancing the reliability of experimental outcomes.

Regulatory Documentation Standards

Maintaining rigorous regulatory documentation is fundamental for operational transparency and successful audits. Compliance with standards such as ISO 9001 involves keeping detailed records, including equipment usage protocols, maintenance logs, and contamination reports. These documents are critical for both operational consistency and audit preparedness. An investigative study suggests that thorough documentation can increase operational efficiency by 20% in laboratory settings. This increase in efficiency not only streamlines laboratory processes but also ensures readiness for any regulatory inspections, thereby reducing downtime and enhancing overall productivity.

Industry Applications and Case Studies

Pharmaceutical Research Scenarios

Glove boxes play a critical role in pharmaceutical research, particularly in handling cytotoxic drugs and sensitive biological materials. Case studies have consistently demonstrated that using glove boxes in drug formulation can enhance both safety and sample quality. For instance, research has shown that integrating glove boxes into pharmaceutical environments can reduce the risk of contamination by as much as 60%, thus ensuring higher integrity and reliability of research outputs. These findings underscore the significant value glove boxes offer in maintaining high research standards and protecting personnel from potential biohazards.

Microelectronics Manufacturing Insights

In the realm of microelectronics, the use of glove boxes is indispensable for isolating delicate components from moisture and particulates, which are crucial factors in maintaining product performance. Manufacturers have observed that incorporating glove box technology can significantly decrease defects in electronic components. Research supports these observations, showing a reduction in product failure rates by approximately 50% when glove boxes are employed during production processes. This not only ensures product longevity and reliability but also enhances the overall efficiency of manufacturing workflows.

Sensitive Biological Sample Handling

For laboratories dealing with sensitive biological samples, glove boxes offer essential benefits by providing a controlled environment crucial for sample viability. Studies indicate that glove boxes effectively prevent contamination from environmental factors, leading to increased survival rates of samples by over 70%. This ability to maintain stringent atmospheric conditions is especially important in fields such as microbiology and virology, where even minor contamination can severely affect the integrity of experimental results. Thus, glove boxes are invaluable in promoting both safety and research accuracy in such environments.

FAQ Section

What is a glove box and why is it important in laboratory settings?

A glove box is an enclosed workspace designed to maintain a controlled environment. It is crucial for laboratory settings as it prevents contamination and provides protection for sensitive samples and research materials.

How does hermetic sealing contribute to glove box technology?

Hermetic sealing ensures that the glove box environment is airtight, protecting the samples from external contamination and preserving their integrity.

What role do inert gases play in glove box systems?

Inert gases such as nitrogen and argon are used in glove box systems to create oxygen and moisture-free environments, essential for preserving samples that may degrade or oxidize easily.

Why are dual-zone transfer chambers significant in glove box systems?

Dual-zone transfer chambers are important because they allow for safe material handling without compromising the protective environment inside the glove box.

How are HEPA filters used within glove boxes?

HEPA filters in glove boxes trap airborne contaminants, preventing them from affecting sensitive samples and ensuring a clean and controlled environment.

Why is atmosphere monitoring critical in glove box systems?

Atmosphere monitoring provides real-time data on gas composition and purity within a glove box, allowing for prompt adjustments to maintain sample integrity.

Table of Contents

- Essential Features of Modern Glove Box Systems

- Contamination Control for Laboratory Samples

- Operational Protocols for Sample Integrity

- Maintenance & Compliance Requirements

- Industry Applications and Case Studies

-

FAQ Section

- What is a glove box and why is it important in laboratory settings?

- How does hermetic sealing contribute to glove box technology?

- What role do inert gases play in glove box systems?

- Why are dual-zone transfer chambers significant in glove box systems?

- How are HEPA filters used within glove boxes?

- Why is atmosphere monitoring critical in glove box systems?