Essensiële instandhoudingsprosedures vir laboratoriumhandskoenkaste

Handskoene se integriteitskontroles en lekvoorkoming

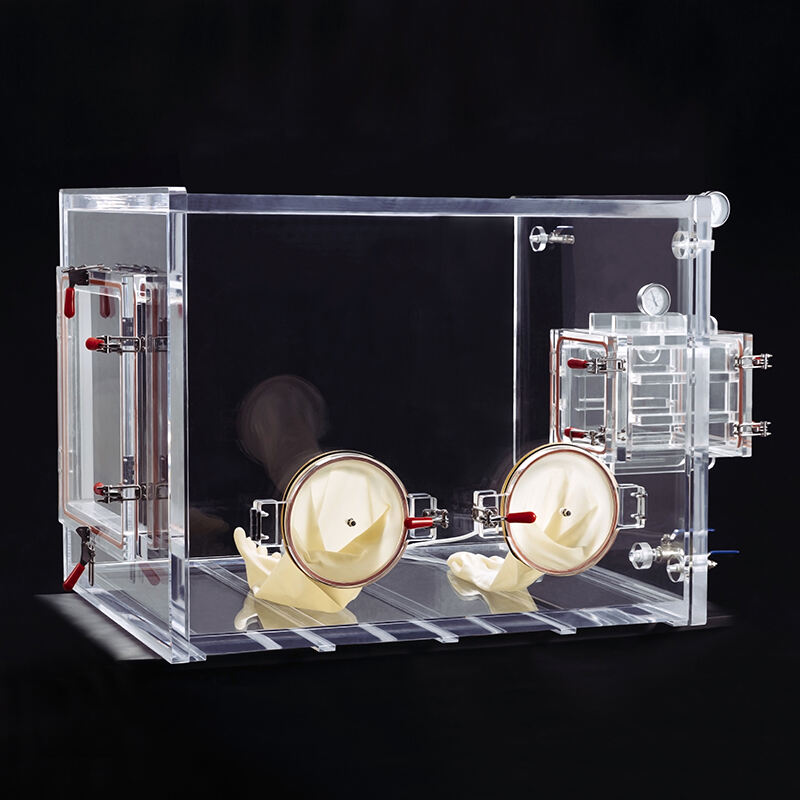

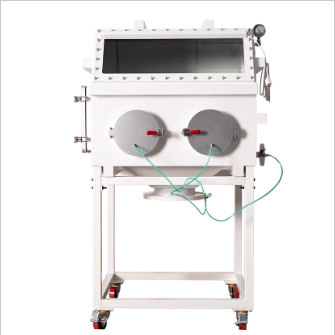

Die uitvoer van gereelde handskoenintegriteitskontroles is noodsaaklik om lekke in laboratoriumhandskoenkaste te voorkom, wat die veiligheid en beheer van sensitiewe eksperimente kan kompromitteer. Ek vertrou op beide opblaas- en onderdompelingstoetse om moontlike breuke op te spoor. Hierdie prosedures help om te verseker dat die handskoene in optimale toestand verkeer om chemiese blootstelling en deurboorings te weerstaan. Ek verstaan die belangrikheid van die gebruik van handskoene wat van hoë-kwaliteit, robuuste materiale vervaardig is. Daarbenewens dokumenteer ek elke kontrole wat uitgevoer word noukeurig. Die handhawing van sodanige deeglike rekords dra nie slegs by tot naspoorbaarheid nie, maar verseker ook 'n proaktiewe instandhoudingsbenadering, wat die risiko van besmetting aansienlik verminder.

Visuele inspeksies vir slytasie en seëlbeskadiging

Rutienvisuele inspeksies speel 'n belangrike rol in die identifisering van slytasie en seilskade in laboratoriumhandskoenboksse. Ek fokus op die gereelde ondersoek van kritieke areas soos handskoenmateriaal, seëls en ander belangrike komponente. Die gebruik van 'n gestandaardiseerde toetslys tydens hierdie inspeksies verseker 'n konstante en deeglike proses. Hierdie toetslys sluit die evaluering van komponente soos ritssluiters, seëls en handskoenpolsdele in. Op grond van die inspeksiebevindinge, implementeer ek 'n vervangingsprotokol wat ooreenstem met die veiligheidsstandaarde van die industrie. Hierdie sistematiese benadering verseker dat enige beskadigde elemente tydig aangespreek word, en so die integriteit en veiligheid van laboratoriumoperasies behou word.

Filtervervangskedules vir Skoonkamerstandaarde

Die hantering van streng filtervervangingskedules is noodsaaklik om skoonkamerstandaarde in laboratoriumomgewings te handhaaf. Ek raadpleeg vervaardiger se riglyne wat op gebruiksfrekwensie gebaseer is om 'n geskikte vervangingstabelle te bepaal. Deur 'n logboek te vestig om filtervervanginge te volg, verseker ek dat daar voldoen word aan die nodige dokumentasie, wat onontbeerlik is tydens regulasie-oudits. Verder opleiding van personeel om teken van filterversadiging raak te sien, stel ons in staat om tydig voorkomstap te neem. Hierdie kennis verminder die waarskynlikheid van onverwagte toerustingstoring en handhaaf die hoë skoonmaakstandaarde wat in laboratoriumomgewings vereis word.

Kalibrasieprotokolle vir Optimum Handskoendoos Prestasie

Suurstof- en Vochtigheidssensor Kalibrasiemetodes

Gereelde kalibrasie van suurstof- en vogtigheidssensore is noodsaaklik om die akkuraatheid van omgewingsbeheer in handskenhokke te handhaaf. Die toepassing van industrie-standaard tegnieke verseker dat hierdie sensore presiese lesings lewer, wat noodsaaklik is om besmetting te voorkom en veiligheid te handhaaf. Die gebruik van kalibrasiegasse en vogtigheidsstandaarde wat geseëvierd is vir akkuraatheid, verbeter die presisie, wat vir laboratoriums belangrik is om hulle metings met vertroue te kan gebruik. Daarbenewens ondersteun die noukeurige dokumentering van kalibrasieprosesse toepasbaarheid en na-voegbaarheid, wat noodsaaklik is tydens oudits en regulasionele hersiene.

Interne teenoor eksterne kalibrasiemetodes

Die kies tussen interne en eksterne kalibrasiemetodes hang af van die spesifieke behoeftes en hulpbronne van 'n laboratorium. Interne kalibrasie kan meer koste-effektief wees en bied groter beheer oor die proses. Eksterne kalibrasiedienste verskaf egter dikwels hoër akkuraatheid as gevolg van spesialistiese toerusting en kundigheid. Konstansie in kalibrasiefrekwensie moet bepaal word deur die gebruik van die handskakelkassie en die blootstelling aan verskillende omgewings. Riglyne verskaf oor die kies van die mees geskikte metode verseker dat laboratoriums hul behoeftes kan bereik deur 'n doeltreffende uitset.

Dokumentasievereistes vir ouditspoor

Die behoorlike dokumentering van kalibrasie-aktiwiteite is noodsaaklik om aan regulerende vereistes te voldoen en georganiseerde rekordhouding te verseker. Laboratoriums moet sterk stelsels inkorporeer vir die handhaving van ouditspoorsnyers, wat elektroniese rekords kan insluit om prosesse te stroomlyn en die gehoorsaam verbeter. Dit behels die logboek van noodsaaklike inligting soos die datum, tyd en resultate van elke kalibrasie. Deur aan hierdie dokumenteringpraktyke te voldoen, kan laboratoriums nie net hul gehoorsaam bewys nie, maar ook 'n betroubare geskiedenis van hul toerusting se werkverrigting handhaaf, wat krities is vir deurlopende verbetering en verantwoordbaarheid.

Verseker Gehoorsaam aan Veiligheid- en Kwaliteitsborgstellingsstandaarde

Voldoen aan ISO- en GMP-laboratoriumvereistes

Die handhaving van ISO- en GMP-standaarde is noodsaaklik vir laboratoriums wat handsakke as deel van hul prosesse gebruik. Hierdie standaarde verseker dat laboratoriums hoë vlakke van gehalteborging handhaaf, wat bydra tot die integriteit en betroubaarheid van die werk wat uitgevoer word. Volgens 'n studie wat in die International Journal of Environmental Science and Technology gepubliseer is, is die handhaving van sulke standaarde nie net 'n regulerende vereiste nie, maar verminder dit ook aansienlik die risiko's wat verband hou met besmetting en onakkuraatheid. Nie-nakoming kan lei tot ernstige gevolge, insluitend finansiële boetes en skade aan reputasie. Daarom is dit noodsaaklik om 'n proaktiewe benadering tot nakoming te handhaaf, wat gereelde oudits en voortdurende personeelopleiding behels om op hoogte te bly van ontwikkelende standaarde en laboratoriumveiligheid te verseker.

Daarbenewens is voortdurende opleidingsprogramme noodsaaklik vir laboratoriumpersoneel om huidig te bly met betrekking tot ISO- en GMP-standaarde. Die beklemtoning van voortgesette opleiding verseker dat alle personeellede die nodige protokolle begryp en toepas om aan die vereistes te voldoen. Hierdie proaktiewe benadering bevorder 'n kultuur van verantwoordelikheid en toewyding, wat direk die betroubaarheid van resultate beïnvloed en die laboratorium se reputasie handhaaf. Opleiding moet beide teoretiese kennis en praktiese toepassing insluit, en verseker dat alle personeellede toegerus is om die kompleksiteit van handskenhok-bedrywe doeltreffend en veilig te hanteer.

Integrasie van instandhouding in gehalteborgprotokolle

Gereelde instandhoudingskontroles is 'n fundamentele komponent van gehalteborgingsprotokolle in laboratoriums wat handskoenkasse gebruik. Hierdie integrasie verseker dat toerusting optimaal werk, en sodoende die akkuraatheid en betroubaarheid van eksperimentele resultate beskerm. Byvoorbeeld, het 'n gevallestudie uit die Tydskrif vir Laboratoriumsorg getoon dat laboratoriums wat sistematiese instandhoudingskontroles in hul gehalteborgingsprotokolle geïnkorporeer het, 'n 25% toename in bedryfsdoeltreffendheid en 'n afname in toerustingverwante voorvalle beleef. Die sinergie tussen instandhouding en gehalteborging kan nie genoeg beklemtoon word nie; dit vorm die ruggraat vir prosedurele konsekwentheid en veiligheid in laboratoriumomgewings.

Dit is noodsaaklik om laboratoriums aan te moedig om 'n holistiese benadering aan te neem wat beide instandhouding en gehalte-assesserings integreer vir langtermynsukses. Hierdie benadering verseker dat potensiële probleme tydig geïdentifiseer en reggestel word, wat sodoende die tyd van werking verminder en laboratoriumoperasies verbeter. Deur 'n omgewing te bevorder wat beide voorkomende en regstellende aksies waardeer, kan laboratoriums 'n balans bereik tussen die handhaaf van huidige operasionele standaarde en die strewe na voortdurende verbetering. Die implementering van gestruktureerde protokolle vir beide gehalteborg en toerustinginstandhouding verseker dat laboratoriums voldoen aan regulasies en standaarde, en uiteindelik hul missie ondersteun om presiese en betroubare resultate te lewer.

Oplossing van algemene probleme met handskenhouders

Hanteer van atmosfeerbeheerprobleme

Atmosferiese beheer is noodsaaklik vir die optimale werking van handsak-bokse, maar dit is nie ongebruiklik om in hierdie opsig te doen nie. Gewoonlik kan foute ontstaan weens toerustingstekortkoming, soos defekte sensore, of omgewingsfaktore wat die stelsel beïnvloed. Ander oorsake kan insluit lekkasies in die stelsel of onkorrekte kalibrering van beheereenhede. Wanneer atmosferiese beheerprobleme ontstaan, behoort die eerste stap in die opsporing van foute te wees om die stelsel se drukmanometers en lugvloeimekanismes te ondersoek op tekens van foutiewe werking. Dit is ook nuttig om kalibreringslogboeke na te slaan om enige afwykings te identifiseer. Werklike voorbeelde beklemtoon beste praktyke; byvoorbeeld 'n geval waar 'n lugvloei-probleem opgelos is deur bloot die sensore weer te kalibreer, wat die doeltreffendheid van hierdie basiese foutsoekstappe aantoon.

Oplossing van besmettingsrisiko's

Om kontaminasierisiko's in handskoenkaste te verminder, is dit noodsaaklik om duidelike protokolle op te stel. Hierdie protokolle moet fokus op prosedure-integriteit en die gebruik van persoonlike beskermingstoerusting (PPE). Kritieke stappe sluit in om te verseker dat alle ingange en uitgange van die handskoenboks aangeteken word, en dat oppervlaktes gereeld ontsmet word om kruisbesmetting te voorkom. Beste praktyke behels die vermindering van direkte kontak met monsters en die gebruik van toepaslike versperringstegnieke om skoonheid te handhaaf. Roetine-risikobeoordelings speel 'n belangrike rol in die identifisering van moontlike besmetting bedreigings, veral as laboratoriumprosedures of materiale ontwikkel. Deur hierdie assesserings gereeld te doen, kan laboratoriums voorkomend optree teen veranderinge wat nuwe bronne van besmetting kan inbring.

Korrigerende Drukfluktuasies

Drukvariasies binne handskenhouders kan eksperimente ontwrig en lei tot moontlike veiligheidsrisiko's. Algemene oorsake sluit in stelsellekkas, foutiewe komponente en eksterne omgewingsveranderings wat die kalibrasie beïnvloed. Die diagnose en herstel van sulke probleme behels gewoonlik 'n deeglike inspeksie van seëls en verbindings vir lekkas, gevolg deur 'n herbeoordeling van die stelsel se kalibrasie-instellings. Deurlopende kalibrasie en instandhoudingsprosedures is noodsaaklik om stabiele drukvlakke te verseker. Vir vinnige verwysing tydens inspeksies kan operateurs 'n toetslys gebruik wat die nagaan van seëls, verifikasie van kalibrasie-instellings en die monitering van omgewingsomstandighede insluit. Dit verseker dat enige afwykings tydig aangespreek word en die doeltreffende werking van die handskenhouer behou word.

Beste Praktyke vir Langtermyn Instandhouding van Handskenhouers

Strategieë vir die Beplanning van Preventiewe Instandhouding

Die ontwikkeling van 'n voorkomende instandhoudingskedule is noodsaaklik om die lewensduur en doeltreffende werking van laboratoriumhandskoendoosse te verseker. Deur gebruik te maak van historiese data en gebruikspatrone, kan laboratoriumbestuurders skedules saamstel wat toestelbehoeftes voorsien, en sodoende onverwagte onderbrekings tot 'n minimum beperk word. Sjablone kan aangepas word om by verskillende laboratoriumomgewings te pas, wat 'n gestroomlynde benadering verseker. Byvoorbeeld, kan die skedulering van gereelde toetse op druk- en vakuumprestasie degradasie oor tyd voorkom. Voorkomende instandhouding is dikwels meer koste-effektief in vergelyking met reaktiewe benaderings, wat noodherstel of toestelvervanging kan vereis. Gereelde instandhouding kan die bedryfskoste verminder en die lewensduur van duur laboratoriumtoerusting verleng.

Personeelstraining oor die korrekte bedryf van handskoendoosse

Dit is belangrik dat personeel goed opgelei word oor die bediening en instandhouding van handskoendoosprosedures om die veiligheid en doeltreffendheid in die laboratorium te handhaaf. Daaglikse opleidingssessies moet geïmplementeer word, waar handige werkswinkels, e-leermodules of simulasiestoetse gebruik word om die personeel se begrip en onthou van noodsaaklike operatiewe veiligheidsprotokolle te verbeter. Hierdie opleidingsmetodes bied praktiese ervaring sowel as die nodige teoretiese kennis, en verseker gereedheid vir verskeie operatiewe situasies. Daarbenewens maak die insluiting van terugvoer-meganismes dit moontlik om die doeltreffendheid van die opleiding te evalueer en kennisgatte vinnig aan te spreek. Hierdie proaktiewe benadering bevorder nie net operatiewe veiligheid nie, maar kweek ook 'n kultuur van voortdurende verbetering en bevoegdheid onder laboratoriumpersoneel.

Vrae wat dikwels gevra word

Hoekom is handskoen-integriteitstoetse belangrik vir laboratoriumhandskoendoose?

Handsakintegriteitstoetse help om lekkasies te voorkom en die veiligheid en beheer van sensitiewe eksperimente te verseker. Gewone toetse verminder die risiko van besmetting deur te verseker dat die handsakke in optimale toestand verkeer.

Wat behels visuele inspeksies van handkassies?

Visuele inspeksies behels die ondersoek van sleutelareas soos handsakmateriaal, seëls en komponente om slytasie en skade te identifiseer. 'n Gestandaardiseerde toetslys help om konsistensie tydens inspeksies te verseker.

Waarom is dit belangrik vir laboratoriums om aan ISO- en GMP-standaarde te voldoen?

ISO- en GMP-standaarde verseker hoë vlakke van gehalteborging, verminder die risiko's van besmetting en onakkuraatheid in handkassies. Nie-nakoming kan lei tot finansiële boetes en skade aan reputasie.

Hoe kan drukveranderings in handkassies reggestel word?

Drukveranderings kan reggestel word deur seëls en verbindings te ondersoek vir lekkasies en die kalibreringsinstellings te herbeoordeel. Deurlopende instandhouding en kalibrering help om stabiele drukvlakke te verseker.

Wat is voorkomende instandhoudingskeduleringstrategieë vir handskakels?

Voorkomende instandhoudingskedulering voorsien toestelbehoeftes deur gebruik van historiese data en gebruikspatrone. Reëlmatige kontroles van druk- en vakuumverrigting voorkom degradasie oor tyd heen.

Inhoudsopgawe

- Essensiële instandhoudingsprosedures vir laboratoriumhandskoenkaste

- Kalibrasieprotokolle vir Optimum Handskoendoos Prestasie

- Verseker Gehoorsaam aan Veiligheid- en Kwaliteitsborgstellingsstandaarde

- Oplossing van algemene probleme met handskenhouders

- Beste Praktyke vir Langtermyn Instandhouding van Handskenhouers

-

Vrae wat dikwels gevra word

- Hoekom is handskoen-integriteitstoetse belangrik vir laboratoriumhandskoendoose?

- Wat behels visuele inspeksies van handkassies?

- Waarom is dit belangrik vir laboratoriums om aan ISO- en GMP-standaarde te voldoen?

- Hoe kan drukveranderings in handkassies reggestel word?

- Wat is voorkomende instandhoudingskeduleringstrategieë vir handskakels?